|

|

|

|

|

|

Welcome to the Australian Ford Forums forum. You are currently viewing our boards as a guest which gives you limited access to view most discussions and inserts advertising. By joining our free community you will have access to post topics, communicate privately with other members, respond to polls, upload content and access many other special features without post based advertising banners. Registration is simple and absolutely free so please, join our community today! If you have any problems with the registration process or your account login, please contact us. Please Note: All new registrations go through a manual approval queue to keep spammers out. This is checked twice each day so there will be a delay before your registration is activated. |

|

|||||||

| The Pub For General Automotive Related Talk |

|

|

|

Thread Tools | Display Modes |

|

|

#1 | ||

|

You dig, we stick!

Join Date: Mar 2006

Posts: 7,461

|

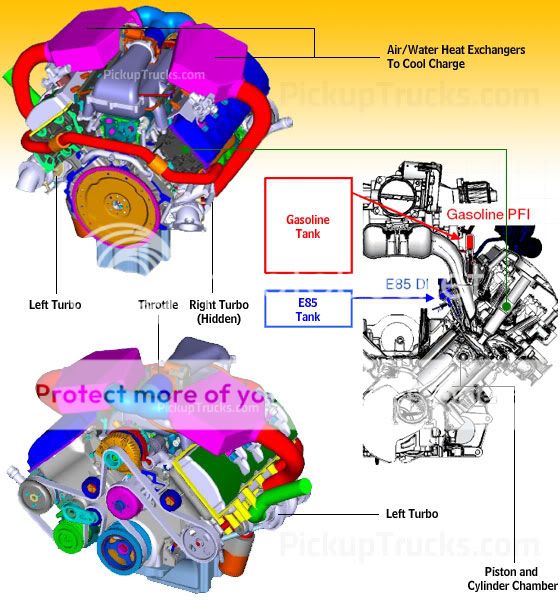

I like the part where is says it's slated for 2012, so it looks

as if it's full steam ahead with this despite some rumours it's dead. By the way, 750lb/ft is just over 1000Nm  Link and link Bobcat: an engine template for the future? By: John Mortimer, 19/05/2009, AutomotiveWorld.com With gasoline and diesel prices in North America around US$2.12 to $2.35 a gallon – half the levels of a year ago – urgency to develop high-performance diesel engines has softened, especially as OEMs face an almost unprecedented financial plight. Ford’s product plans, for example, see its 4.4-litre V8 diesel for the F-150 delayed until 2013. As many OEMs lack diesel engines for light-duty trucks and sports utility vehicles, pressure will grow for high performance gasoline engines with the power and torque, fuel economy and clean emissions of a diesel, especially with demands to raise CAFE standards. This raises the question of whether compacted graphite iron (CGI) will find use for cylinder blocks of North American V8 gasoline engines. Under a shroud of secrecy, Ford, AVL and Ethanol Boosting Systems (EBS) of Cambridge, Massachusetts, working with the US Department of Energy, are testing an engine called Bobcat. Five new ‘ethanol boost’, twin-fuel turbocharged engines have been built and each variably blends gasoline and ethanol to produce diesel-like performance. Bobcat engines run on E85, a mix of 15% gasoline and 85% ethanol and with such technology, a 5-litre engine could potentially produce diesel-like 500bhp and 750lbft torque. Bobcat uses a secretly-sourced CGI cylinder block which helps the engines cope with stress levels associated with high combustion pressures. It is believed Ford aims to use Bobcat in flex-fuel vehicles running on gasoline, ethanol or any combination of the two. EBS claims its technology gives a 30-35% efficiency gain at one third of the cost of a gasoline electric hybrid, but this technology also requires a strengthened engine structure such as might be found with CGI. The CGI engine structure is essential to deal with 150bar peak cylinder pressures. Increased bolt diameters are likewise essential. Fitted to a Ford F-series truck, a spark ignition engine optimised for E85 could give 15-20% fuel economy gains compared with a production gasoline engine and would meet at least ULEV ll/Tier ll Bin 5 requirements. E85 is used only as required at high loads to avoid knock, leaving the efficiency of gasoline improved by using a high compression ratio downsized engine. The technology requires special cylinder heads, including variable cam timing, twin turbochargers with waste gates, special port injection of both fuels, and two high-pressure pumps driven by inlet camshafts. Also, EBS requires a second fuel tank or a separate tank-in-a-tank. In a car, this second tank for E85 could be replenished (5 gallons per 5,000 miles) at the dealer – like the urea refill for diesel SCR. A production vehicle is slated for 2012. EBS is also believed to be working with Mack Trucks/Volvo AB for heavy-duty vehicle applications. Ricardo also is working on ‘optimised’ spark ignition engines with diesel-like efficiency. Ricardo’s system, Ethanol Boosted Direct Injection, uses a 3.2-litre GM gasoline engine to give the equivalent 660lbft peak torque of GM’s Duramax 6.6-litre diesel. However, the Ricardo engine uses a grey iron block with a special cradle to support the crankshaft. The engine has bespoke aluminium cylinder heads.

__________________

"....You don't put the car through engineering" - Rod Barrett. Last edited by Falc'man; 21-05-2009 at 08:47 PM. |

||

|

|

|

|

|

#2 | ||

|

Pity the fool

Join Date: Jan 2007

Location: Wait Awhile

Posts: 8,997

|

Sounds expensive and complicated.

|

||

|

|

|

|

|

#3 | ||

|

King of the Fairy's.

Join Date: Jan 2007

Location: CeeeeeTown.

Posts: 5,093

|

I'm not familiar with "CGI". Does anyone know what its supposed to be?

I know its used to abbreviate Computer Generated Image, but from the article I don't think that is what they are reffering to.

__________________

|

||

|

|

|

|

|

#4 | |||

|

You dig, we stick!

Join Date: Mar 2006

Posts: 7,461

|

Quote:

http://findarticles.com/p/articles/m...4/ai_82321958/ Essentially, there are three types of iron associated with engine blocks: * Gray iron * Nodular iron * CGI Each of these, because of their physical makeup at the microstructure scale, has different machining characteristics. In gray iron, the graphite is in the form of flakes; these flakes help machining because of the way that they fracture when being machined. While gray iron isn't abrasive, nodular iron is. in nodular iron, the graphite is in spherically shaped nodules, which are surrounded by an iron carbide shell, which don't have the same cracking behavior as the flakes in gray iron. During machining, the nodular iron, which has a higher shear strength than gray iron, doesn't come off in small chips; the chips tend to be much more continuous. There are both more concentrated loads and heat generated by the cutting tool in cutting the nodular iron, which contribute to a reduction in tool life. CGI has graphite that resembles coral; the form of the graphite structures, as is the case with nodular iron, is fundamentally controlled by the amount of magnesium in the mix. The microstructure of the CGI material is such that there aren't the stress risers and fault lines associated with gray iron, nor are there the thermal requirements characteristic of machining nodular iron. So because CGI is in the middle of the easy-to-machine and the highly abrasive, one might appropriately imagine that machining should be a fairly straightforward thing.

__________________

"....You don't put the car through engineering" - Rod Barrett. |

|||

|

|

|

|

|

#5 | |||

|

FF.Com.Au Hardcore

Join Date: Nov 2006

Location: Sydney

Posts: 1,334

|

Quote:

What I can't understand is why they're using that over aluminium. Even though aluminium is much weaker, it's less than 1/3 the weight, which means you can drastically increase the thicknesses. If audi can be so successful with their R10 TDi cars then I don't see why anyone else couldn't be. Maybe it's down the the vibration and sound dampening of the CGI. |

|||

|

|

|

|

|

#6 | ||

|

King of the Fairy's.

Join Date: Jan 2007

Location: CeeeeeTown.

Posts: 5,093

|

Natio sounds good. 215s on the mazda this week hopefully.

Thanks for the info. First time I've heard of it. I know Nodular and Grey. I even pulled out my Materials program and it didn't know what I was on about. All sounds pretty promising. Although with 2 turbos and 5lts you'd want to have some impressive numbers.

__________________

|

||

|

|

|

|

|

#7 | |||

|

He has, the Knack..

Join Date: Jun 2006

Location: Sydney

Posts: 1,042

|

Quote:

__________________

2010 BF MKIII Falcon wagon "EGO" Workhorse, stock as a rock 2004 BA MKI Futura - Now the wife's For Show: 18" Kaotic Shadow Chrome, King SL all round, Cadence Amp, Kenwood 12" Sub, JL Audio 5x7's, Scuff Plates, MP3 Connector For Go: SVI LPG, K&N Filter, F6 CAI, XR6T snorkle, XR8 catback, Magnaflow metal cat, Pacemaker headers, Underdrive, Thermostat, Custom tune, DBA4000 Now with baby seat and toys 175.6 rwkw www.bseries.com.au/King_Nothing |

|||

|

|

|

|

|

#8 | |||

|

FF.Com.Au Hardcore

Join Date: Nov 2006

Location: Sydney

Posts: 1,334

|

Quote:

|

|||

|

|

|

|

|

#9 | |||

|

IWCMOGTVM Club Supporter

Join Date: Sep 2005

Location: Northern Suburbs Melbourne

Posts: 17,797

|

Quote:

__________________

Daniel |

|||

|

|

|

|

|

#10 | ||

|

FF.Com.Au Hardcore

Join Date: Aug 2005

Location: Utah

Posts: 3,479

|

I would love it, read about this a while ago. I could see this going in a range of vehicles. F350, Mustang, GTHO, Fiesta..... :-)

|

||

|

|

|

|

|

#11 | ||

|

You dig, we stick!

Join Date: Mar 2006

Posts: 7,461

|

lol at Fiesta.

Madmelon, it's the pressures this system produces that probably puts Aluminium out of the question. Yes, you can increase the size, but wouldn't there be a space issue when doing so?

__________________

"....You don't put the car through engineering" - Rod Barrett. |

||

|

|

|

|

|

#12 | |||

|

FF.Com.Au Hardcore

Join Date: Nov 2006

Location: Sydney

Posts: 1,334

|

Quote:

Alloy diesels and 'bobcats' may become more common, but probably after everyone else has moved to magnesium like BMW... |

|||

|

|

|

|

|

#13 | ||

|

Oo\===/oO

Join Date: Jan 2007

Location: Tamworth

Posts: 11,348

|

sounds promising! Alloy blocks have some flaws, so it good to see a alternative. The Use of E85 is a positive aswell, its a more logical idea then hybrids/electric cars.

I think the aftermarket will love this! Superstrong Crate motors!

__________________

|

||

|

|

|

|

|

#14 | ||

|

FF.Com.Au Hardcore

Join Date: Jan 2008

Location: brisbane

Posts: 1,316

|

Dont V8 Super cars use E85 and still get 650 HP

|

||

|

|

|

|

|

#15 | |||

|

FF.Com.Au Hardcore

Join Date: Jan 2005

Posts: 1,463

|

Quote:

|

|||

|

|

|

|

|

#16 | |||

|

FF.Com.Au Hardcore

Join Date: Nov 2006

Location: Sydney

Posts: 1,334

|

Quote:

|

|||

|

|

|

|

|

#17 | |||

|

FF.Com.Au Hardcore

Join Date: Jan 2005

Posts: 1,463

|

Quote:

Also they could raise the price by $5 and still manufacture using a $5 to produce cheaper component, then they would be further better off. |

|||

|

|

|

|

|

#18 | ||

|

You dig, we stick!

Join Date: Mar 2006

Posts: 7,461

|

Sneak Peek! Ford's "Bobcat" Dual Fuel Engine

A radical twin-fuel engine from Ford, code-named “Bobcat,” that variably blends gasoline and ethanol on demand to realize diesel-like performance continues to make steady progress in its development, according to presentations made by the automaker to the Department of Energy and Society of Automotive Engineers in April. The presentations also provide a first look at the engine’s architecture and make some remarkable claims about “E85-optimized” engine efficiency versus size. The Bobcat engine starts with a small turbocharged engine with separate gasoline and ethanol (E85) fuel injectors for each cylinder. The gasoline system mixes fuel and air in the motor's intake manifold using port injection. The second system uses direct injection to introduce small amounts of ethanol directly into the combustion chamber to control premature detonation, or knock, which results from the high temperature and pressure of a turbocharged engine. The ethanol prevents knock by cooling the air/fuel mixture until the engine is ready for combustion. With knock suppressed, the compression ratio can be increased. Ford’s engineering partner, Ethanol Boosting Systems, LLC of Cambridge, Mass., has trademarked the term “DI Octane Boost” to describe the process; the direct injection of ethanol effectively increases the octane of regular gasoline from 88-91 octane to more than 150 octane. The percentage mix of gasoline and ethanol varies according to load. In low- to medium-load conditions, only port-injected gasoline may be required. Direct-injected ethanol is added and increased as a function of load but only in the amount necessary to prevent knock. Using such technology, a 5.0-liter V-8 Bobcat engine could potentially produce 500 horsepower and 750 pounds-feet or more of torque. Two 3-D computer-rendered diagrams included in Ford’s DOE presentation show the front and rear views of such an engine using a 90-degree V-block design. Two massive air/water heat exchangers sit atop the engine to cool turbocharged air before it enters the throttle body and intake manifold. Twin turbos sit on the lower right and left sides. A separate engine cutaway diagram of a Bobcat motor shows the positioning of a gasoline port injector and ethanol direct injector. The gasoline and ethanol would be stored in two separate fuel tanks.  EBS claims that relative to today’s common port fuel injected gasoline engines in cars and light-duty trucks, direct-injection ethanol boosting would provide a fuel efficiency gain for typical combined city/highway driving of 25 to 30 percent, at an incremental cost of $1,100 to $1,500, depending on the size of the vehicle. The efficiency gain and torque are comparable to current turbodiesel engines, like Ford’s 350-hp/650 lbs.-ft. 6.4-liter Power Stroke, but at about a third of the cost and with the advantage of cleaner emissions without expensive exhaust aftertreatment hardware. Ethanol boosting also promises 5 to 10 percent greater fuel economy than Ford’s new line of gasoline-turbocharged direct-injection EcoBoost engines, which it’s based on. Ford’s DOE presentation says, “The E85 optimized engine and the dual fuel concept are logical extensions of Ford’s ‘EcoBoost’ strategy.” Another way to measure efficiency, regardless of engine architecture, is through a metric called Brake Mean Effective Pressure. BMEP quantifies the amount of work an engine can do versus its displacement by measuring the average pressure exerted on an engine’s pistons. The more efficient an engine is, the higher its BMEP score. According to Ford’s SAE presentation, an experimental 3.5-liter GTDI EcoBoost engine modified with E85 direct injection and gasoline port fuel injection run on a dynamometer achieved a BMEP score of 305 psi (27 bar), which translates to approximately 553 pounds-feet of torque and 316-hp at 3,000 rpm (flat torque curve from 1,500 to 3,000 rpm). The experimental engine was limited by the engine block’s ability to handle higher compression ratios. In comparison, a standard GTDI EcoBoost engine on a dyno was rated at 17 bar, which translates to approximately 350 pounds-feet of torque and 300-hp at 4,500 rpm (flat torque curve from 1,500 to 4,500 rpm). As we mentioned earlier, ethanol use increases with engine load. A potential drawback to the Bobcat engine would be access to an ethanol refueling infrastructure, especially when a truck is working hard pulling a trailer or climbing hills. Ford’s SAE presentation provides several range estimates for refueling a 5.0-liter Bobcat V-8 with a 10 gallon E85 tank and 26 gallon gas tank compared to a current Ford F-150 with a 5.4-liter V-8 and 26 gallon gas tank. Under mild driving conditions, the 5.0-liter E85 tank might have to be refilled only once every 20,000 miles and the gas tank refilled every 528 miles. Today’s 5.4-liter V-8 is said to have a 486 mile range under these conditions. However, an extreme towing scenario with the 5.0-liter V-8 pulling a fully-loaded trailer up a constant 6 percent grade could mean refilling the E85 tank as often as every 100 miles. That would be more often than the gas tank, which has an expected range of 243 miles under those conditions. Today’s 5.4-liter V-8 is said to have a 99 mile range under these conditions. If the ethanol tank did run dry, the Bobcat engine could operate indefinitely with lower performance using only gasoline until a source of E85 could be found. Under most operating conditions, however, Ford’s Bobcat engine could be the right powertrain at the right time to meet newly mandated corporate average fuel economy requirements that require fuel efficiency standard for all light trucks (crossovers, pickup trucks, SUVs and vans) to rise to 30 mpg by 2016, from 23.1 mpg today. Will it work in the real world? Ford will try out its theories outside of computer simulations and the laboratory before the end of the year when a Bobcat engine is tested in an F-Series pickup for the first time. Link. ========================================== Now, this is one truck motor we should have.

__________________

"....You don't put the car through engineering" - Rod Barrett. |

||

|

|

|

|

|

#19 | |||

|

Rob

Join Date: Sep 2006

Location: Woodcroft S.A.

Posts: 21,334

|

Quote:

its all well and good comparing to these engines, but like you say, they are race engines. sure they are under extreme conditions, esp in 24hr events, but they aren't built for longevity. race engines are only built to do a fraction of the miles of a road going engine. |

|||

|

|

|

|

|

#20 | ||

|

FF.Com.Au Hardcore

Join Date: Mar 2005

Location: Newcastle

Posts: 3,246

|

Thanks Falc'man.

Here's another good link. It's a PDF with some graphs and timelines. http://www1.eere.energy.gov/vehicles...8_aagarwal.pdf

__________________

BA2 XR8 Rapid M6 Ute - Lid - Tint -18s 226.8rwkW@178kmh/537Nm@140kmh 1/9/2013 14.2@163kmh 23/10/2013 Boss349 built. Not yet run. Waiting on a shell. Retrotech thread http://www.fordforums.com.au/showthr...1363569&page=6 |

||

|

|

|

|

|

#21 | |||

|

FF.Com.Au Hardcore

Join Date: Mar 2005

Location: Newcastle

Posts: 3,246

|

Quote:

__________________

BA2 XR8 Rapid M6 Ute - Lid - Tint -18s 226.8rwkW@178kmh/537Nm@140kmh 1/9/2013 14.2@163kmh 23/10/2013 Boss349 built. Not yet run. Waiting on a shell. Retrotech thread http://www.fordforums.com.au/showthr...1363569&page=6 |

|||

|

|

|

|

|

#22 | |||

|

FF.Com.Au Hardcore

Join Date: Nov 2006

Location: Sydney

Posts: 1,334

|

Quote:

|

|||

|

|

|

|

|

#23 | |||

|

FF.Com.Au Hardcore

Join Date: Dec 2004

Location: Canberra Region

Posts: 8,868

|

Quote:

__________________

2016 FGX XR8 Sprint, 6speed manual, Kinetic Blue #170 2004 BA wagon RTV project. 1998 EL XR8, Auto, Hot Chilli Red 1993 ED XR6, 5speed, Polynesian Green. 1 of 329. Retired 1968 XT Falcon 500 wagon, 3 on the tree, 3.6L. Patina project. |

|||

|

|

|

|

|

#24 | |||

|

You dig, we stick!

Join Date: Mar 2006

Posts: 7,461

|

Thanks for the contribution, Phil. Saw that a while ago, very good read.

Quote:

Madmelon, you done your homework like Martin has?

__________________

"....You don't put the car through engineering" - Rod Barrett. |

|||

|

|

|

|

|

#25 | ||

|

FF.Com.Au Hardcore

Join Date: Nov 2006

Location: Sydney

Posts: 1,334

|

Yeh sorry it looks like I'm wrong :(

I was certain it was based on the R10 V12 which ,most definitely IS an alloy block engine (As is the R15 V10). Seems journalists take having 12 cylinders and being turbo diesel as being "based on". CGI block, alloy heads. Wrong. That's not to say it's not possible to make an extremely strong, light weight, reliable alloy block turbo diesel. The VW Touareg and Subaru Boxer Diesel both use an alloy block from my reading. |

||

|

|

|

|

|

#26 | |||

|

You dig, we stick!

Join Date: Mar 2006

Posts: 7,461

|

Quote:

__________________

"....You don't put the car through engineering" - Rod Barrett. |

|||

|

|

|